The only way to keep your knives at their best is by regularly sharpening them. Keeping knives (and other blades) sharp is also the easiest way to help reduce the risk of blade-related accidents. Unless you are lucky enough to have a local sharpening service, then sharpening them yourself with a sharpening stone is one of the main ways keep your knives at their best.

There are three main types of sharpening stone or whetstone, and in this article, we give an overview of these, particularly focusing on the water stone and the oil stone. We also give you the lowdown on grits and why you may need to occasionally flatten a sharpening stone. We also review a number of bestselling sharpening stones to help you to find the best sharpening stone for your blade requirements.Quick Comparison: Top 10 Best Sharpening Stones

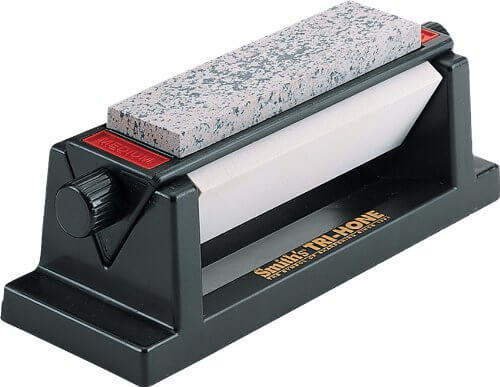

1. Smith’s TRI-6 Arkansas TRI-HONE Sharpening Stones System

Assembled in the US from imported components, the Smith’s TRI-6 Arkansas TRI-HONE sharpening stones system contains a natural medium Arkansas stone and a natural fine Arkansas stone along with a coarse synthetic stone. Suitable for sharpening and honing a range of blades, these three stones are mounted on a rotating plastic triangle so you can rotate the stones depending on which stone you want to use.

The rotating triangle is mounted on a molded plastic base with non-slip feet and a trough to catch drippings. This also has an angle guide. This sharpener is best used with a honing oil (small bottle supplied), although water can be used as a substitute.

The odd buyer has found that the stones can sometimes come loose from the mount and the oil supplied with the stone is only a small bottle, so you will need to buy more. For residents of California, this comes with a Prop 65 warning.Pros

Cons

2. BearMoo Whetstone Premium 2-IN-1 Sharpening Stone

With 3000 and 8000 grit sides, the BearMoo 2-in-1 sharpening stone is a whetstone made from professional grade aluminum oxide. Suitable for sharpening knives and tools, this sharpening stone has a non-slip silicone base to hold it in place and it also comes with a satisfaction guarantee.

The 3000 grit side is a fine grit for putting an edge on the blade while the 8000 grit is for finishing and polishing the edge. This is a water sharpening stone, so no oil is required. Some owners consider that the 8000 grit is not as fine as it should be for that grit grading and they have found themselves using this stone to just put an edge on a blade and then using a different stone to finish the edge. There can also be a risk of the stone coming apart; especially when being pre-soaked before use.

Pros

Cons

3. Shun 300/1000 Combination Whetstone

The dual sided Shun combination whetstone is a 300/1000 grit whetstone. The 300 grit is for sharpening blades and the 1000 grit allows you to hone them. This Japanese-manufactured stone requires water for sharpening, comes in a gift box and with a non-slip base that helps you maintain the correct angle when sharpening.

The odd buyer has found this stone a little small for easily sharpening longer knives and the 1000 grit for honing may not always be fine enough when honing Japanese knives.Pros

Cons

4. CWINDY Sharpening Stone

Made from Japanese imported aluminum oxide, the CWINDY 2-in-1 sharpening stone is a dual 1000/6000 grit whetstone. Ideal for sharpening knives and tools, this stone does not require any oil for sharpening, instead it should just be pre-soaked in water. This also comes with a non-slip base, an eBook guide and a satisfaction guarantee.

The odd user has found that this stone can be on the softer side and start to wear down quite quickly and the odd stone can be chipped on the corner when received.Pros

Cons

5. Kota Japan Dual Sided Water Stone Kit

The Kota Japan dual sided water stone kit is a 400/1000 grit sharpening stone for sharpening knives and tools. As a water stone, this should be soaked in water before use and then the blade can be sharpened with the 400 grit and then finished with the 1000 grit.

This stone has a bamboo base with non-slip rubber feet and an angle guide and eBook. It also has a 30 day satisfaction guarantee and an unconditional lifetime warranty. The odd buyer has found this stone needs soaking for much longer than recommended and there is a small chance of receiving it damaged.Pros

Cons

6. Sharp Pebble Premium Whetstone Knife Sharpening Stone

The double sided SHARP PEBBLE sharpening stone is a universal dual-sided 1000/6000 grit whetstone sharpener for sharpening knives, chisels, axes and other blades. Made from aluminum oxide, this stone comes with an angle guide and a non-slip bamboo base with a silicone mat to hold the stone in place while sharpening. This also comes with an eBook of tips.

As a water stone, this uses water rather than oil for sharpening. Some buyers consider this could be better quality and others have found the sharpening instructions less than clear. As this is a dual stone there is also a risk of the two stones coming apart with use – especially when soaked in water.

Pros

Cons

7. Norton 614636855653 IB8 India Combination Oilstone

Made from aluminum oxide, the Norton Combination India oil stone (614636855653 IB8) has been pre-filled with oil to allow oil to stay on the surface of the stone during sharpening. This dual sided oil stone has 100 grit on one side for developing/repairing the blade edge and 320 grit on the opposite for sharpening/maintaining the edge.

A number of buyers are disappointed to find that this stone is now made in Mexico rather than the US and it also comes with a Prop 65 warning for residents of California. The stone may not always be completely flat, which can be an issue when sharpening certain toolsPros

Cons

8. ShaPu Whetstones Premium whetstone knife sharpening set

Comprising four dual-sided sharpening stones, a non-slip acacia wood base, flattening stone and angle guide, the Whetstone sharpening set also comes with a carry case. The whetstone grits are as follows: 240/800, 600/1500, 1000/3000 and 5000/10,000 and made from aluminum oxide, these stones require water for sharpening with.

Suitable for sharpening a wide range of blades, this sharpening set also comes with a one year limited warranty. The odd buyer considers that the grit gradings are not always accurate and some of the stones have actually needed flattening before use.

Pros

Cons

9. Naniwa 1,000 Grit Super Ceramic Water Stone with a Base

The Naniwa 1000 grit water stone is an aluminum oxide whetstone bound with magnesia for rapid sharpening of more difficult blade materials such as high alloy steels. Made in Japan, this stone comes with a non-slip base and a dressing stone for cleaning/flattening the whetstone.

This type of whetstone is occasionally prone to cracking with normal use and as this stone is attached to the base, it means you cannot turn it to keep its wear even.Pros

Cons

10. Masuta Natural Sharpening Honing Stone

The ‘Ocean Blue’ natural Tsushima sharpening stone is sourced from a now-closed underwater mine near South Tsushima Island, Japan. This stone has an ultrafine grit of around 12,000 for honing and mirror edge sharpening of knives and tools and also comes with a silicone anti-slip pad.

This is a larger 9" by 4" stone which also comes with a matching slurry stone; used to create slurry on, and clean and flatten the whetstone. An occasional buyer has commented that they do not consider this to be a round a 12,000 grit, when compared to other higher grit stones and as a natural Japanese water stone, this is a premium priced stone.

Pros

Cons

Things to Consider Before Buying A Sharpening Stone

Sharpening stones, whetstones or water stones sharpen straight steel knife and tool edges by grinding and honing. Sharpening stones are split into different types, with the most common types being water stones and oil stones. Diamond stones are also used for some types of sharpening.

Most manufacturers provide guidance on how to use their sharpening stone and although sharpening is a skill that takes time to acquire, being able to sharpen your kitchen knives and other tools such as pocket knives, axes and chisels makes it a skill well worth developing.

When choosing a whetstone, a 6" stone is usually adequate for sharpening kitchen knives, but if you do want to sharpen larger tools, then a larger whetstone will be easier to work with.

The Water Stone

Water stones are available as natural and synthetic stones. Japanese water stones are natural stones often used as a honing stone or for polishing with. A harder stone, often preferred by sharpeners who are more experienced, a Japanese water stone can give a mirror finish to the blade edge. A Japanese water stone also carries a premium price tag, especially as many of the mines where the stones were sourced are now closed.

If you are looking to buy a Japanese stone, then an arato or coarse stone will have a 2300 to 800 grit, a nakato or middle stone can be from around 800 to 15000 and a shiageto or finishing stone will be around 1500 upwards.

A synthetic water stone is usually made from aluminum oxide, the same material as India stones. Water stones are softer than India stones as the binder which holds the abrasive (aluminum oxide) in the stone breaks away easier to then be replaced with fresh and sharper material. This means that sharpening on a water stone is faster however, this softness also means that it will wear down faster and because it often wears down unevenly, it will need flattening to bring it back into shape.

Synthetic water stones can be available in grit grades from a 100 to 10,000 grit, although a higher grit may not always be as fine as it should be, generally, the lower the grit, the more accurate the sizing will be. The lower the grit grade, the coarser the stone, which means that more metal will be removed from the edge of the blade.

Synthetic water stones can be especially useful when sharpening stainless steel Western-style blades. Synthetic stones usually always need soaking in water before use and keeping moist throughout sharpening.

The Oil Stone and Honing Oil

Oil stones cut slower than water stones and because oil is used for cutting with it also means there is more mess cleaning up the swarf (metal chips).

The oil stone is the type of stone that most of us are familiar with; a natural oil stone is also known as an Arkansas or novaculite stone. Novaculite stone is quarried in Arkansas and the grades of the stone usually range from around 500 to 6000 grit, although like other natural whetstones, these are not measured to an exact grit, as there is also natural variation.

Instead, they are known as soft Arkansas (finer grit), hard Arkansas, hard black Arkansas and hard translucent Arkansas. The last two of these are rarer stones and will therefore cost more to buy. There is also a washita grit which is rarely used as it is a very soft stone.

The advantage of grit variation in Arkansas and other natural sharpening stones is that this creates various micro-serrations in the blade edge which means that the blade will wear down at different rates – keeping the edge for longer.

Arkansas stones are extremely hard and will rarely need flattening although they can take longer to sharpen with. If you want a mirror finish you will find this harder to achieve with an Arkansas stone. Some people may use water to sharpen with an Arkansas stone rather than oil. If you want to try water, then do so before you use oil; as once oil has been used, you will not be able to use the stone with water.

Applying oil to an oil stone not only carries away the waste coming off the blade edge, it also helps keep the blade angle consistent and reduces the heat that is produced by friction. This heat can slightly warp a blade, and although to some extent water can reduce friction, oil is much better at reducing the heat.

Honing oils usually contain highly-refined mineral oil, a light oil that will not harden or turn rancid. Mineral oil is also odor-free and will not release any fumes. Honing oil may also contain other additives such as detergents.

When applying oil to an oil stone, it should be rubbed in rather than just pouring over and if you do not have honing oil to hand, then other light oils can be used. It needs to be a light oil as a heavier or viscous oil will prevent the stone from sharpening properly.

Oils such as vegetable oils should not be used as these will harden and clog the stone - stopping it from working properly. These types of oils can also turn rancid or give an ‘off’ smell over time.

Synthetic oil stones can be made from aluminum oxide or silicon carbide. The India stone is a synthetic oil stone which is able to cut fast and develop a fine edge on tools and knives.

India stones are usually orange or brown colored and they tend to be graded as fine, medium and coarse. Silicon carbide stones are also graded in this way. Usually gray colored, these are also fast cutting stones but as silicon carbide stones struggle to produce a fine edge, they are best used as a general coarse sharpener. You can then use a finer stone for finishing/honing with.

The Diamond Stone

Made from small industrial diamonds which are usually attached to a metal plate, diamond stones do not need flattening and have a long lifespan. However, these are aggressive stones which will wear down an edge if you are not careful and as coarse grit stones, they cannot hone or finish a blade.

Grits and Gradings

Like sandpapers, whetstones are usually graded by their grit. A grit of less than 1000 is a coarse grit stone suitable for removing chipped edges or nicks in a blade. It can also undertake rough sharpening, such as when your knife has completely lost its edge. A coarser stone like this should not be used too often as it will eventually wear your knife down.

A whetstone of 1000 to 3000 grit will sharpen ‘normally’, such as a knife that has dulled with use. Grit graded at 2000 or above will take off any fine scratches and burr left by a coarser stone, while 4,000 upwards will hone/finish a sharp blade edge and give a mirror finish.

A number of experts suggest that a stone graded above 10,000 will not make any measurable improvement to an edge.

If you are new to sharpening, then a dual sided 400/1000 whetstone is ideal to start with as this will allow you to repair any minor chips and assess sharpening as you proceed, while not scratching the knife.

Maintaining a Sharpening Stone

A sharpening stone’s lifespan can be lengthened by always using it on a level surface, avoiding sharpening bulkier tools on a softer stone, sharpening the blade at the correct angle and using all parts of the stone.

Cleaning the stone after use is also important. Usually just washing a water stone will clean it after use, but if it is particularly dirty, then you can spray some WD-40 on it then rub steel wool over it in circles. This will usually bring up most of the dirt. The stone can then be washed thoroughly under running water to remove the remaining WD-40. As WD-40 is kerosene-based rather than oil-based, it makes suitable for cleaning water or oil stones with.

Over time, a whetstone will start to dip, often in the middle. A small dip may not always cause issues with sharpening, but when sharpening some types of knives, or tools such as chisels, on a stone with a dip will cause problems.

A water stone which is dished is one which is taking on an uneven surface; often because certain parts of the whetstone have been used more often than other parts.

To straighten out a dished whetstone, or remove a dip from it, you will need to flatten it. If you can lay an engineer’s square or straight edge across your stone and see a gap between the square and the stone, then it needs flattening.

If you hear someone refer to a ‘loaded up whetstone’, this means the stone is loaded up with metal chips and other bits. This can also be removed by flattening and making sure your knife and hands are clean before you begin sharpening can help prevent loading up in the first place.

To flatten a whetstone, you will need a flat, coarse stone called a flattening stone or lapping plate. Flattening is quite easy to do. You will need to mark your whetstone with pencil lines and then under running water, or with both stones wet, run the water stone over the lapping plate in a circular motion to cover the full surface of the stone. As you do this, the pencil marks will start to disappear from the whetstone. Once the pencil lines are gone, the stone is now lapped.

You can then use the engineer’s square again (or similar) to check that the gap between the square and water stone has now disappeared.

If you do not want to buy a flattening stone, then a 100 grit wet-dry sandpaper can also help flatten a stone. You can then use a 400 grit paper to remove any scratches caused by the wet-dry from the surface of the stone.

After using a whetstone, it should always be left to dry out for a couple of days before putting it away. If it is still damp when you put it away it may develop mold and can decrease in quality.

Conclusion

In this article we have looked at the difference between natural and synthetic stones, as well as the pros and cons of oil, water and diamond stones and what grit gradings actually mean when sharpening. We have also offered a number of tips to help you get the most from your stone, including how to flatten it when it develops a dip.

We hope that you have found our article on sharpening stones useful; whether you are a sharpening novice or seasoned pro. We also hope that our reviews of ten of the best sharpening stones has been useful and that you now feel comfortable selecting the right stone for your kitchen and household blades.

Related Posts

The 12 Best Zesters in 2023

The 10 Best French Fry Cutters to Make Restaurant Style Fries At Home

The 8 Best Cutco Knives Review in 2023